Hydraulic press machines are fundamental in a variety of industries, ranging from manufacturing to automotive repair. Their ability to exert force via hydraulic means, offering precise control, has made them invaluable in numerous applications.

If you’re in the market to source one of these machines for your business, ensuring you get the right fit is crucial for operational efficiency and safety. Here are 5 expert tips to guide you in the process:

Determine the Specific Application

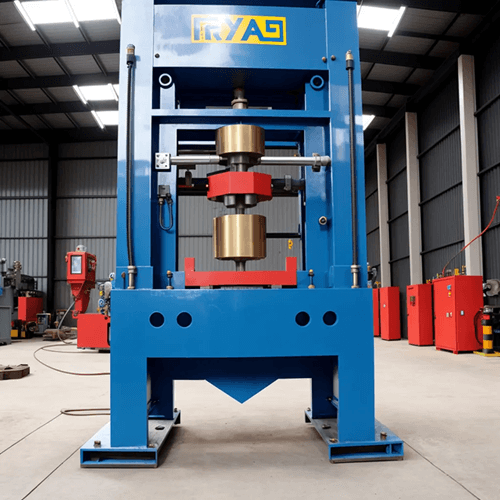

Before diving into the market, it’s essential to define the primary purpose of the press. Are you looking to stamp, form, mold, or press-fit? The application dictates the type of hydraulic press you’ll need. For instance, a C-frame press might be ideal for a job requiring easy accessibility, whereas a straight side press can handle higher capacities with better precision.

Consider the Capacity & Size

Hydraulic presses come in a wide range of capacities, typically measured in tons. Determine the maximum force you’ll require for your operations. This will narrow down the choices considerably. Alongside capacity, the size of the machine matters too. Ensure the machine can fit within your workspace without causing obstructions or safety hazards.

Inspect the Safety Features

Hydraulic press operations can be dangerous if the machine isn’t equipped with adequate safety features. Look for machines with built-in pressure relief valves, guards, and emergency stop buttons. Some advanced models may also feature light curtains or two-hand operating controls, which can further reduce the risk of accidents.

Prioritize Quality & Brand Reputation

While budget constraints are a reality for most businesses, it’s essential not to cut corners when sourcing an industrial hydraulic press. Trusted brands have built their reputation on delivering durable and efficient machines that stand the test of time. Even if it means a slightly higher upfront cost, investing in a quality machine can save money in the long run by reducing maintenance costs and minimizing downtime.

Seek Post-Purchase Support

A good hydraulic press supplier doesn’t just disappear post-sale. They should offer comprehensive post-purchase support, which includes installation guidance, training, maintenance, and access to spare parts. Additionally, consider warranties or guarantees provided by the manufacturer as they can be indicative of the machine’s quality and the trust the manufacturer places in its product.

Read more here about all kinds of hydraulic press machines and see how good the deals are with this manufacturer.