Mindblown: a blog about philosophy.

-

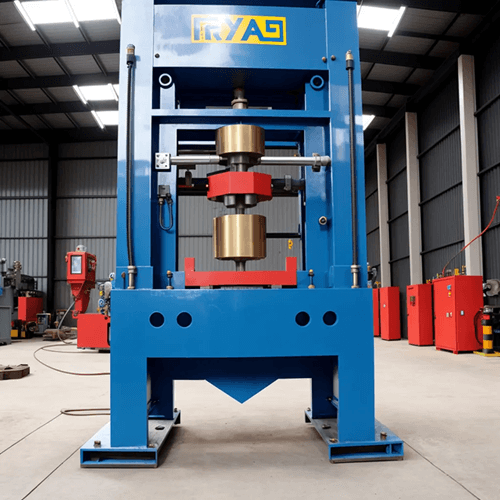

Sourcing An Industrial Hydraulic Press Machine – 5 Newbies’ Hacks

Hydraulic press machines are fundamental in a variety of industries, ranging from manufacturing to automotive repair. Their ability to exert force via hydraulic means, offering precise control, has made them invaluable in numerous applications. If you’re in the market to source one of these machines for your business, ensuring you get the right fit is…

-

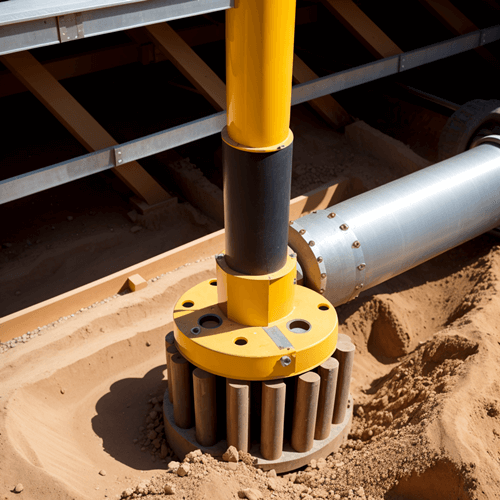

5 Things To Look For When Choosing Drilling Tools

Drilling tools are integral to various industries, from construction and manufacturing to oil and gas exploration. The choice of the right tool can make all the difference in ensuring the success of a project and optimizing efficiency. Whether you’re a seasoned professional or a DIY enthusiast, it’s essential to select the best tool for the…

-

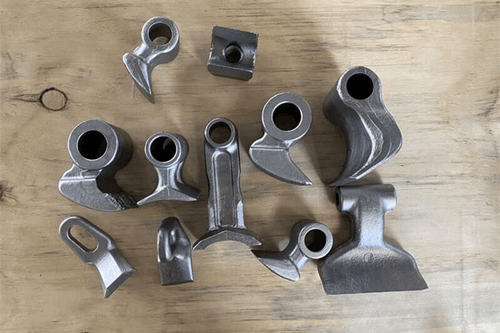

A Good Drilling Tools Manufacturer Must Have These 5 Traits

In the booming world of construction and mining, drilling tools are indispensable. As such, choosing the right drilling tools manufacturer can determine the efficiency, productivity, and safety of your operations. Identifying the perfect manufacturer isn’t about finding one that simply churns out tools. Instead, it’s about identifying one with certain key traits that signify quality,…

-

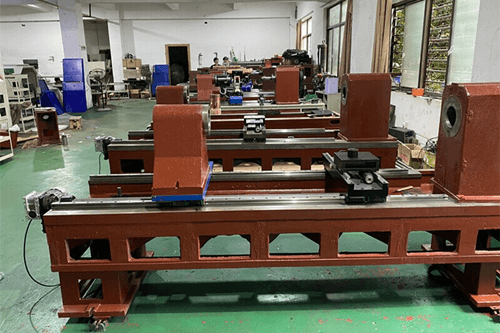

The Best Automated Hydraulic Press To Buy Must Have The Following

Buying an automated hydraulic press can be a significant investment for many businesses, particularly those in the manufacturing, automotive, aerospace, and industrial sectors. This critical piece of machinery can offer impressive power and efficiency when chosen correctly. To assist in the process of decision-making, we have gathered some key features to consider when evaluating and…

-

Why Expertise In Flexo Printing Is A Crucial Component

In today’s fast-paced business world, companies are constantly seeking innovative ways to enhance their brand identity and attract consumers. One crucial aspect of this endeavor is the printing process, which plays a significant role in delivering high-quality packaging, labels, and other printed materials. Flexo printing is one the widely used method in branding. But why…

-

Why Quality Of Tools Is Key In Foundation Drilling – 5 Advantages

Foundation drilling is a crucial process in construction projects, as it forms the basis upon which buildings and structures stand. The success of foundation drilling depends not only on skilled operators but also on the quality of tools used. Investing in high-quality tools can significantly impact the efficiency, safety, and overall outcome of foundation drilling…

-

Tips to keep FAE mulching head teeth sharp

One of the greatest inconveniences you can ever have is dealing with a mulcher whose teeth are blunt. It will take you a long time to achieve your stipulated operational goals. It is not only inconvenient but also disruptive to handle a mulching task using blunt blades. That is why you must always ensure that…

-

Things to Consider in Choosing Aftermarket W6 Road Milling Bit Manufacturer

With the aftermarket sector growing bigger by the day, you can easily get confused in choosing the right manufacturer for W6 road milling bit. Maybe you have already tried to choose one and ended up being stuck. Well, the last thing you want is to deal with a manufacturer who will never meet your expectations.…

-

Best Hacks For Selecting Mulcher Teeth Manufacturers

The best way to buy mulcher teeth is to plan and get a few things right before going to the market. This is important, especially for those buying for the first. Among the important things that you need to consider is the manufacturer. There are so many manufacturers in the market, and you are not…

-

This Is What You Need To Make High Quality Flexo Printing Plate

This Is What You Need To Make High Quality Flexo Printing Plate The quality of the flexo printing plates is a key factor when it comes to flexography printing. This is crucial, especially if you are in the printing business. Without quality plates, then it will be difficult to deliver quality printing. So what makes…

Got any book recommendations?